top of page

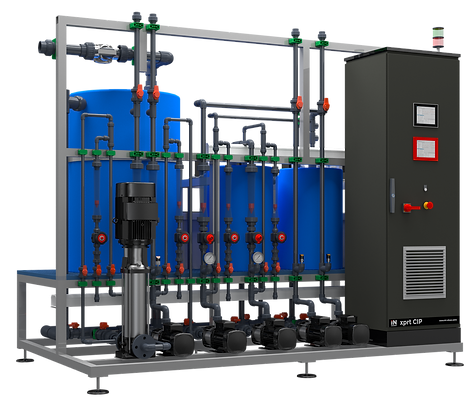

Our XPRT CIP units have been designed to provide accurate, consistent, and permanent (24/7) availability of hydration solution for flowers and washing solution for fruits and vegetables. The unit can be customized with the number of solutions and dosing channels your operation requires. In some of our options we can integrate a CIP (Cleaning in Place) unit with a high-pressure pump equipped with a double nozzle for cleaning the floor or machinery, as well as a spray nozzle for surface disinfection.

For more Information download the professional datasheet.

01

CAPACITY

-

P01 - 4 m3/h (Hydratation - Sol. 1)

-

P03 - 4 m3/h (Hydratation - Sol. 2)

-

P05 - 4 m3/h (Hydratation - Sol. 3)

-

P06 - 5 m3/h (Cleaning)

02

DOSING CHANNELS

-

4 dosing channels

-

5 dosing pumps

bottom of page